Follow Us

Katy Spring & Manufacturing, Inc.

Katy Spring is a Houston, Texas-based company with its custom spring manufacturing facility located in Katy, Texas. We manufacture custom metal components including compression springs, torsion springs, extension springs, wire forms, flat springs and assemblies for a wide range of markets including oil and gas, chemical, medical, agricultural, automotive, aerospace, lawn and garden, recreational, chemical, refining, electronics, robotics, marine and high-tech, and food services, just to name a few.

Our

QualityPolicy

“It is the policy of Katy Spring & Mfg. to deliver quality products on time, made to the specifications of our customers.

Our goal is to help our customers succeed. To achieve our goal requires a commitment to continuous improvement in an environment of honesty, sincerity, and mutual respect.”

Our Products

From Our Blog

Spring Squareness

Spring squareness refers to a compression spring, and how perpendicular it is, typically for ground ends. It is difficult to make the ends square within three degrees of a compression spring that is not ground flat. The spring shown requires the ends to be within...

Large Capacity Heat Treat

Katy Spring has large capacity, high-temperature ovens that can age-harden high-nickel alloy materials such as: Inconel, Inconel X, Elgiloy, 17-7 Stainless, Monel, K Monel, Hastalloy and more! Contact us today for your high nickel, custom spring requirements....

Spot Weld

Katy Spring can spot weld 300 series stainless as shown in this video. Stainless steels are engineered materials capable of meeting a broad range of design criterion. Stainless steel has excellent corrosion-resistant properties and high strength in...

Optical Comparator

Katy Spring utilizes optical comparators to ensure quality, custom wire form parts. The optical comparator (profile projector) has been used in quality control in the manufacturing industry since 1925. The design has changed little in that...

Stainless Steel Torsion Spring – Made in Texas!

This torsion spring is made from .022 3000 series stainless steel. The spring is used in a scientific application. Springs like this are made on a CNC wire bender which promotes speed, consistency, and repeatability. Does your company purchase custom torsion springs...

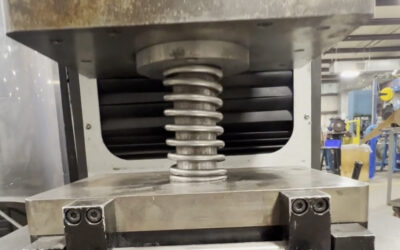

Introducing Katy Spring’s new LS-20000 preset machine

Katy Spring’s new LS-20000 preset machine information. - Cycle testing up to 4000 lbs.- Presetting up to 4000 lbs.- CNC capable Cycle testing springs is deflecting a spring over the course of a given amount of time at a certain rate that provides documentation of a...

Industries Served

Oil and Gas

Oil and Gas Service Equipment

Downhole Tools

Mechanical Seals

Medical

Valves

Chemical (Catalyst)

Trucking

Compressors

Agriculture

Security Gates

Instrumentation

Actuators

Regulators

HVAC

Pumps

Fasteners

Pipeline Inspection

Fiber Optics

Cable Connectors

Aerospace

Electrical Transformers